This is a big deal! MACH Machine Tools wins two separate tenders

Published: | Milling, lathes, machining centres

MACH Machine Tools wins two separate tenders, worth over £850k in total, to supply Newcastle College with a range of manual mills and lathes, and a suite of innovative 3-axis vertical machining centres.

The 24 new machine tool acquisition is an integral part of a Newcastle College investment programme designed to significantly upgrade the capacity and capabilities of its engineering facility, with the hope it can become a recognised ‘Centre of Excellence’ with students, apprentices, local and regional employers and the wider community.

MACH Machine Tools, part of the Vigilance Group, and a supplier of high-quality CNC and manual machine tools and machine shop equipment to UK and Irish component manufacturers as well as a growing number of FE and HE institutions, has recently supplied Newcastle College, part of the NCG group of colleges, with 16 new manual machine tools, and eight new vertical machining centres.

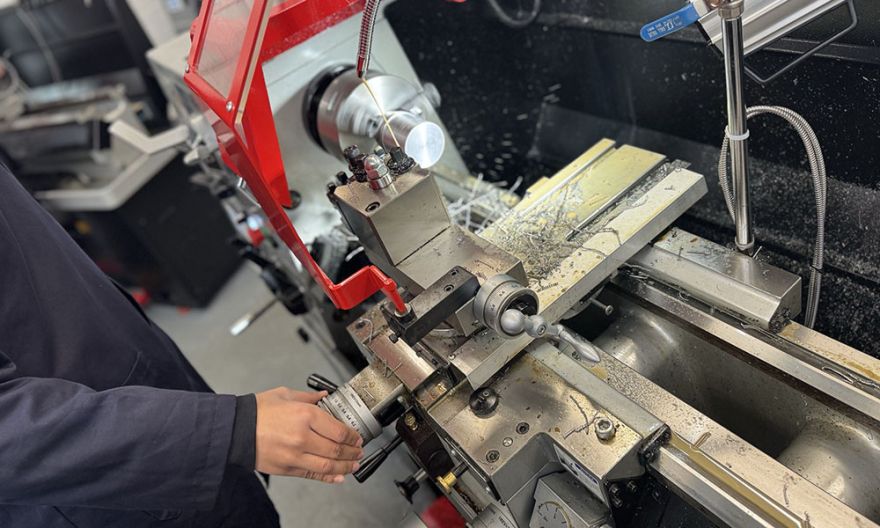

The machines, comprising eight MACH VS-1SP turret-type manual milling machines, eight MACH L-1340 manual lathes and eight MACH MDV 700-DT vertical machining centres, were delivered and installed, last year, at Newcastle College’s dedicated Advanced Manufacturing Suite in two tranches - the manual machines arriving in July 2024 and the CNC machines arriving in October 2024.

The MACH machines tools acquired by Newcastle College are an impressive and represent a formidable front-line engineering resource that will be used to deliver practical, relevant and Industry-required machining knowledge and skills to the Colleges’ full-time and part-time engineering students, and apprentices.

The investment not only reflects the College’s commitment to continuous improvement but also underpins its intention to create a world-class engineering training facility at its main Rye Hill Campus site that will help raise its profile and further differentiate its course provision with key target audiences.

Engineering: Raising the profile…meeting the need

There is, and always has been so it seems, much debate in the UK - at national, regional and local levels - about making careers in engineering, and manufacturing in general, more attractive and appealing to young people.

Running parallel to these discussions is a recognition, made more acute by the pandemic and, more generally, by the continuous upheaval in, and dislocation of, traditional global supply chains, that UK manufacturing needs to be more resilient, more productive and more competitive.

However, a major stumbling block to achieving these objectives remains the perennial skills shortage issue, experienced by many, if not most, UK manufacturers, and engineering companies in particular.

Explains Mark Goodall, Head of Engineering, Newcastle College: “As a vocational college we operate in a competitive environment where young people have a number of choices open to them at 16, 17, 18 and beyond.

“As one of the region’s largest colleges, supporting the education, training and employment of thousands of people in the local area, and developing a skilled workforce for local employers, we need to be attracting highly motivated and dedicated students onto our further education and higher engineering courses, and onto our apprenticeship programmes.

“One of our biggest priorities is working in partnership with our local employers to ensure that our curriculum meets their recruitment needs - now and in the future – and that we are able to provide them with a large pool of highly-skilled labour, to ensure their long-term growth and prosperity.

“Critical to attracting and retaining students and increasing engineering employers’ participation and involvement, are the training facilities we have at our disposal.”

“If the technology and equipment we are using to train students doesn’t match up with what’s being used in the world of work, we won’t be achieving our goal of preparing students for their future employment, or a addressing the skills gap in what is a priority area of growth in the North East.”

The recent investment made in new MACH manual and new MACH CNC machine tools by Newcastle College has to be viewed against this backdrop.

Investing in the new technology – the process

The upgrade of its engineering capabilities and resources at its Rutherford Building facility is a never-ending process: a journey rather than a destination, so to speak.

In late 2023, Newcastle College made the decision to completely modernise and revamp its manual and CNC machine tool capabilities within its (two) engineering workshops as a route to transforming the practical and skills-based content of its engineering courses.

As part of the investment process, two different open tenders inviting potential suppliers to submit detailed proposals for the supply of a range of manual machines (lathes and milling machines), and a suite of CNC vertical machining centres, were prepared and advertised.

The two tenders were mutually exclusive with interested suppliers being able to bid for either or both tenders.

Says Carmelo Catalanotto, Advanced Technical Lecturer, Newcastle College: “The tenders were essentially aimed at machine tool manufacturers and suppliers and recognised that not all potential suppliers would have manual and CNC machines in their product portfolios.”

Tender success

As part of the College’s robust procurement procedures an extensive evaluation process followed after the submissions’ closing date, with every tender invitation reviewed against the published evaluation criteria and weightings, to determine the most economically advantageous and best-value submission.

MACH Machine Tools, with its extensive CNC and manual machine tool line-up combined with its knowledge and experience of the FE and HE sectors and its range of customised and augmented services it can provide to educational organisations, was able to score highly with both of its tender submissions.

As a consequence, MACH Machine Tools’ two tenders were successful, and the company was awarded both contracts.

MACH Machine Tools’ tender responses were successful for a number of reasons which included the following:

- The technical quality, price and availability of the machine tools recommended.

- The level of service and support, including delivery, installation and training provided.

- The scope, scale and value of ‘social’ support provided (i.e., sponsorship, promotions and advertising, Master Classes etc.).

Continues Mark Goodall:

“MACH Machine Tools submitted two competitive tenders that represented real value and included a number of advantages that the other suppliers could not match.

“We hadn’t dealt with MACH Machine Tools previously, and it was really encouraging to see a company prepared to ‘go the extra mile’ to win our business.”

Manual machine package: a closer look

The eight MACH VS-1SP (milling machines) and eight MACH L-1340 (lathes) have helped transform Newcastle College’s manual machine workshop.

Prior to the investment, the College’s manual machine resources comprised eight older lathes and one older vertical mill which were ‘long in the tooth’ and created issues from both a teaching and learning perspective.

Says Carmelo Catalanotto: “The manual machine investment was vital and was made to satisfy two key criteria.

“Firstly, we needed new, modern and reliable machines for students to understand and learn basic milling and turning principles, and to become proficient in different machining operations.

“Secondly, we needed to increase the number of manual machines we had at our disposal so that students could learn new skills and put them into practice on a machine by themselves or in pairs, rather than in groups.

“Our investment in MACH manual machine tools means that all students now have access to, and can be taught on, the same high-performance machines.”

MACH manual machines are built to last and include standard technology features that on many competitor machines are only available as optional extras.

VS-1SP mills

MACH VS-1 SP turret type milling machines have a small footprint and are equipped with large-capacity worktables and powerful spindles.

The machines are built to exacting quality standards and deliver high accuracies, fast processing speeds and are equipped with 1245mm x 229mm worktables with a 340kg table load, 5,000rpm spindles and DROs (Digital Read Outs).

L-1340 lathes

MACH L-1340 lathes are compact machines equipped with quick-change tool posts and tailstocks, and feature anti-vibration and stress relieved beds, backlash eliminators and 2-axis DROs.

As part of the manual machine tool package, MACH Machine Tools also arranged to remove the older manual machines from the College’s workshop before installing the 16 new machines.

CNC machine package: a closer look

The eight MACH MDV 700-DT 3-axis vertical machining centres have joined a number of other 3- and 5-axis CNC machines previously acquired by the College.

Continues Carmelo Catalanotto: “Similar to the rationale for investing in the MACH manual machines, we needed a number of high-specification machining centres to enable students to acquire, and try out, their newly acquired CNC machining skills and, for more advanced students, to develop their manual, CAD and conversational programming and post-programming skills and expertise.

“We believed that eight identical CNC machines would be the optimum number we would require, from both a workshop space and classroom size perspective.”

MDV 700-DT

MACH MDV 700-DT machines are fast, powerful and precise.

The machines were supplied (as requested) with the advanced Fanuc 31i-B5 Plus control and are equipped with 12,000rpm high-speed, direct-drive BT 30 spindles, 21-tool ATCs and a toolholder and cutting tool package for each machine.

The machines also feature oil/mist extraction units.

In addition to their Fanuc control, the machines were further supplied, and integrated with, a unique MACH Programming Station - a Windows-based PC that sits alongside each machine and features a custom-designed version of the DynaPath software and a Fusion 360 CAD/CAM package that is networked to every machine’s Fanuc control.

Says Carmelo Catalanotto: “The advanced Fanuc control enables us to teach students the fundamentals of ISO programming, using G-and M-codes, and the inclusion of the MACH Programming station also means we have access to (and can use) many innovative DynaPath software features as well.

“These include the ability to take advantage of conversational programming and the facility to create complete machining programs directly from DXF files.

“The inclusion of Fusion 360, an industry-leading and recognised CAD/CAM software package, also provides us with the inherent flexibility to design and generate machining programs complete with full simulation and reliable toolpath verification.”

Summary

Newcastle College has significantly increased the capacity and capabilities of its engineering facilities through its investment in MACH Machine Tools’ manual and CNC machines.

Full-time and part-time students are already being taught milling and turning skills on the new VS-SP mills and L-1340 lathes and, in the next few weeks, the College’s new MACH MDV 700-DT machining centres will begin to be used.

A key objective behind Newcastle College’s investment in new, advanced manual and CNC machines was to mirror, and indeed replicate, machining technologies used in today’s, and tomorrow’s, modern engineering machine shops and workshops.

Even a cursory glance at the College’s new facilities, replete with the new machines and previously acquired tool setters and CMM inspection equipment in the CNC area, suggests that they have more than met this objective.

For further information please contact: Matt Andrew -

MACH Machine Tools https://www.machinetoolsalesonline.com

Quick Links

Published By

4 Mayfair Court

Cleethorpes

South Humberside

North East Lincolnshire

DN35 0QG

© Copyright Roger Barber Publishing , all rights reserved.

Terms and Conditions apply. This website uses cookies, click here for blocking details. Our Privacy Policy is available here.