75th anniversary of VE Day recognises T W Ward’s wartime efforts

Published:

Last Friday marked the 75th anniversary of VE Day,

a celebration and opportunity to remember all of those that fought so hard for us during the Second World War. “To those who gave so much, we thank you.”

To mark the celebration, the British public were encouraged to share stories and memories of those who lived through the war. T W Ward CNC Machinery Ltd (Ward CNC) therefore wanted to share the Ward Group’s contribution to the war effort during the 1939-45 period.

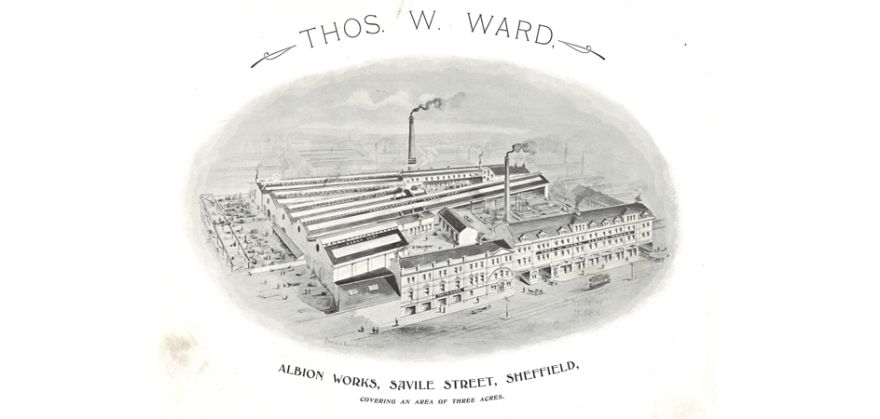

Ward CNC is still proud to be at these premises and is certain that those that have visited it recently would agree that it is looking very different from then?

Infrastructure & Machine Tool Reconditioning

During World War II, the Group had notable involvement in the construction of roads, runways, and railway sidings. The company’s expertise of machine tool reconditioning was vital at the time to war production and utilised to the full.

When it was decided to remove the nation’s aircraft factories to secret sites less vulnerable to enemy bombing, Ward was entrusted with the huge task of moving and reinstalling the hundreds of machine tools and ancillary equipment used at the many plants. It was accomplished with a loss of less than twenty-four hours’ production time per machine. Lord Beaverbrook described the job as ‘the most gigantic of its kind in history’.

Ward Machine tool advert – one of the company’s adverts published during this time for which the same principles of the company apply today

Mulberry Harbour and PLUTO

Many other wartime projects involved Ward. Two of these have passed into history: Mulberry Harbour and PLUTO. The two prefabricated ports of Mulberry, each the size of Gibraltar, were manufactured in sections, and towed to their destination off the coast of Normandy. Ward coordinated the supply and distribution of materials for this unique construction, which greatly simplified the problem of maintaining supplies to the Allied Armies in Europe. Ward excavators were called upon for PLUTO, or the ‘pipe-line under the ocean’, by which fuel was fed in vast quantities across the Channel.

Mulberry Harbour – a project in which the Ward Group played an active part in the construction

A unique contribution to the war effort

It is noteworthy that during this time, Ward had become the parent of a diverse group of companies, each of which made its own unique contribution to the war effort. This included: midget submarines, tanks and naval guns, from Marshalls of Gainsborough; cranes, winches and excavators from Smiths of Rodley and Smiths of Keighley; specialised castings from Widnes Foundry; huge tonnages of cement from Ketton for airfields, roads, defence constructions; the many wartime civil engineering projects throughout the country.

Ward was also instrumental in rescuing the famous Triumph car manufacturing company from oblivion. Triumph got into difficulties around this time and Ward purchased the assets and goodwill in August 1939 and part of the factory was used during the war for making aero engines and components.

Salvage operations

There were many difficult and dangerous salvaging operations to carry out throughout the war, including the demolition of almost 100 vessels ranging from submarines to the 56,000 tonne liner ‘Majestic’. Such was the reputation of Ward in this activity that when the ‘Graf Spee’ was scuttled by her German crew outside Montevideo harbour, it was the company’s experts who were flown to the scene.

When hostilities ceased, Thos. W. Ward Ltd. was again at the centre of the mammoth job of clearing up. Bomb-damaged sites were levelled, construction equipment and materials provided for their redevelopment. The many skills of the Ward group were now focused upon the task of serving industry in an increasingly competitive post-war world.

“Ward’s Might Have It”

An acute awareness of the value of good publicity gave rise to the known slogan “Ward’s Might Have It” attracting both national and international recognition as a wide-ranging source of industrial goods.

TW Ward CNC Machinery Ltd

Tel: 0114 276 5411

Email:

www.wardcnc.com

Quick Links

Published By

4 Mayfair Court

Cleethorpes

South Humberside

North East Lincolnshire

DN35 0QG

© Copyright Roger Barber Publishing , all rights reserved.

Terms and Conditions apply. This website uses cookies, click here for blocking details. Our Privacy Policy is available here.