A GibbsCAM distributor since 1988

Published:

Tech CADCAM is celebrating 30 years as the UK distributor for GibbsCAM.

The Suffolk-based company distributor has been bringing innovation to the manufacturing industry since 1988.

Tech CADCAM offers a range of innovative and intuitive CAM software products which aim to be simple to learn and productive to use.

The company’s highly experienced team is able to assess your needs and find the right combination of software, support and service to allow your business to excel and achieve its full potential.

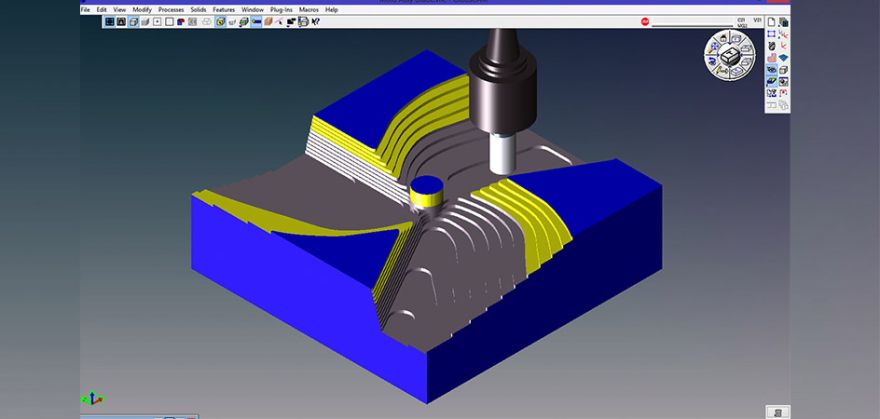

GibbsCAM is a cutting-edge CAM system for programming CNC machine tools and has the power and flexibility to let you make parts the way you want. With its easy-to-navigate shop-friendly interface, you’ll maximise productivity. Whether CNC programmer, machinist or manufacturing engineer, the user will find familiar terminology. Icons will make sense and processes will be logical. With GibbsCAM, CNC programming is flexible, fast, reliable, and efficient.

GibbsCAM programs any CNC milling, turning, mill-turn or wire EDM machine. From 2-axis turning and 2.5 axis milling, to 3-, 4- and 5-axis simultaneous and the most complex multi-spindle, multi-turret, multi-tasking and Swiss-style MTM machines, GibbsCAM drives them all.

The interface icons are easily understood and the menu structure flat, so programmers don’t have to step through menu after menu to get something done. It enables quick navigation and fast programming for experienced programmers and rapid learning for new programmers.

Whatever CAD format your customers, designers or engineers prefer to use, that’s the format that GibbsCAM will read or open directly and accurately, so you can quickly modify part models for machinability.

Accurate, flexible and reliable toolpath creation

GibbsCAM reads, translates, creates, modifies and machines part features with precision. It provides multiple ways to drive cutting tools, including high-speed machining strategies, so parts can be programmed and machined your way. It saves tools and processes, so you can quickly program a family of parts or react to engineering without having to reprogram the entire part.

Toolpath simulation with collision detection, which is available at any point in the programming, shows tool motion and rendered surface finish, highlighting gouges and unwanted cuts for fast error correction.

From the most complex multi-axis machine, to the simplest, GibbsCAM Machine Simulation can prevent costly errors at the machine, and greatly reduce on-machine prove-out.

GibbsCAM was developed to be efficient for the programmer, efficient for the machinist and efficient at the machine. With GibbsCAM you’ll get more programs done faster, you’ll get higher accuracy and reliability, plus you’ll spend less time testing and proving programs. You’ll get faster cycle times and more parts out the door, to keep more customers satisfied.

Tech CADCAM Ltd

Tel: 01284 754781

Email:

www.techcadcam.net

Quick Links

Published By

4 Mayfair Court

Cleethorpes

South Humberside

North East Lincolnshire

DN35 0QG

© Copyright Roger Barber Publishing , all rights reserved.

Terms and Conditions apply. This website uses cookies, click here for blocking details. Our Privacy Policy is available here.