DMG MORI announces PFronten Open House

Published: | News

Expertise in 5-axis machining, freely scalable automation and integrated manufacturing processes for high precision and productivity in every manufacturing process will be the themes of DMG MORI’s next open house, to be held at its Pfronten factory in southern Germany from 26th to 30th January for the German, Austrian and Swiss markets, and from 2nd to 6th February for all international guests.

During the two weeks, trade visitors from all over the world will experience solution-oriented machining concepts for companies of all sizes. The focus will be on industry-specific applications in the aviation and space, data and semiconductor, and die and mould sectors.

Cornelius Noess, Chief Managing Director of DMG MORI Pfronten commented, "We combine future-proof machining technologies with integrated processes, automation, digital solutions and reliable service throughout a production system’s entire life cycle.

"In this way, we demonstrate to companies of all sizes, especially small and medium size enterprises, that modern manufacturing does not have to be complex if production systems are holistic, modular and tailored to the customer’s requirements."

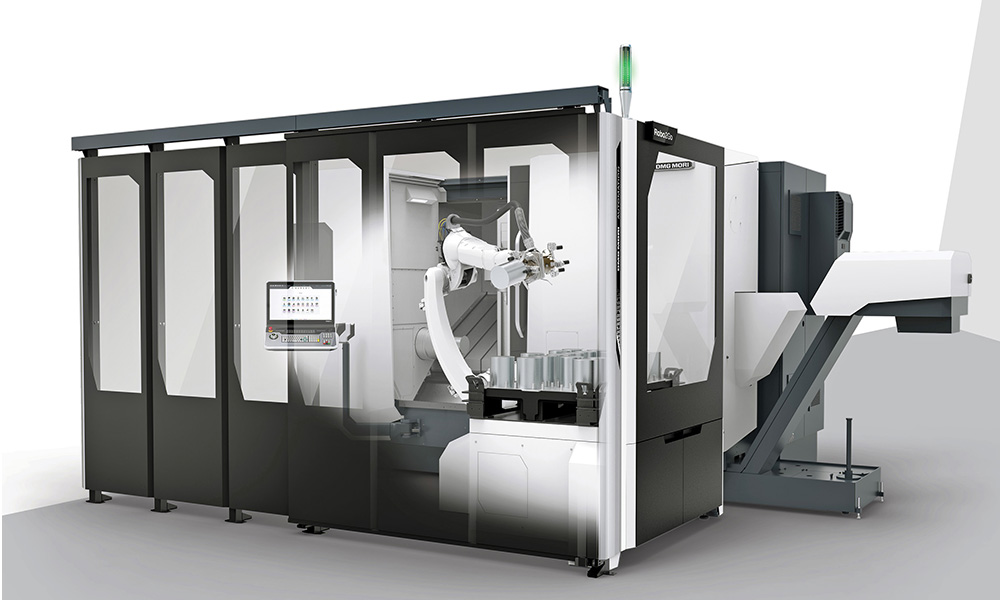

DMG MORI will be showing over 40 machines and more than 20 automation solutions across an area of 4,500 square metres. The focus will be on four world premieres, one of which is the new CTX 450 4A universal turning centre, which offers optimal connectivity for networked production.

In the field of powder nozzle additive manufacturing, a LASERTEC 65 DED hybrid will be launched that is capable of subtractive machining as well, plus other processes. There will be a 2nd generation DMU 65 H monoBLOCK 5-axis horizontal machining centre, also with a high degree of process integration. Finally, the Robo2Go 3rd generation will be an automation premiere. All innovations exemplify the path that DMG MORI is consistently pursuing in the further development of its product range.

The manufacturer’s extensive machine and automation portfolio offers flexibility to meet all the requirements of modern production, be it single part or large series. In addition to turn-mill centres and advanced prismatic machining production platforms, ULTRASONIC models and vertical multi-process grinding machines from the Vertical Mate series will be on display. Additionally, there will be powder bed as well as direct energy deposition additive manufacturing systems on show.

In a dedicated automation area, the use of driverless transport systems will be demonstrated. For the autonomous handling of machine pallets, material pallets, chip carts and tools, mobile robots will show how entire production processes on the shop floor can be implemented without human intervention.

Another highlight at the Pfronten site will be the opening of a new training centre, where the next generation of young talent will be nurtured. While the DMG MORI Academy has been supporting the education of young engineers for many years in cooperation with training workshops and educational institutions, the machine tool manufacturer also attaches great importance to an optimal learning environment within its own company. Around 150 apprentices, trainees and degree apprentices will be prepared here for the challenges of Industry 4.0.

Rounding off the open house programme will be seminars on MX - machining transformation - and associated manufacturing solutions. It is DMG MORI's four-tiered approach to addressing problems prevalent in global manufacturing, namely a shortage of skilled workers, high energy costs, slow production times and complicated software.

Quick Links

Published By

4 Mayfair Court

Cleethorpes

South Humberside

North East Lincolnshire

DN35 0QG

© Copyright Roger Barber Publishing , all rights reserved.

Terms and Conditions apply. This website uses cookies, click here for blocking details. Our Privacy Policy is available here.